My car departs Geneva one last time towards the northern reaches of Switzerland. This will be my third and final manufacture visit on the trip. Everything was a blur after a gruelling week of watch viewing but by now, the route is familiar. Driving by Lake Geneva with the mountain line visible in the distance offers views one never tires of.

Fun fact: Lake Geneva spans 581km², roughly 79 per cent of Singapore’s land mass of 735.7km². The route snakes up from Geneva, as with the previous two visits; this time, however, we turn up the winding hills of Neuchâtel instead of driving past. Perched on an upslope, flanked by trees and brushed by alpine air without gilded fanfare, the Panerai Manufacture reveals itself with modern restraint, perhaps as a nod to its military past.

After moving its workshop beyond Italian borders to the Swiss canton overlooking Lake Neuchâtel in 2002, Panerai expanded into this larger facility, further advancing its suite of highly specialised inhouse production capabilities. The facility was inaugurated in 2014 and combines the ingenuity and excellence of Italian design with traditional Swiss expertise.

Those privy to Panerai’s storied past would know of its roots as suppliers of precision instruments to the Italian Royal Navy as far back as 1916 under the tutelage of Giovanni Panerai. It was not until 1993 that the brand made its watches available to the public.

Much of the Panerai aesthetics echo those of the past, including the iconic crown protecting device, cushion-shaped case and luminous sandwich dial construction. While the watches appear simple on paper, they are more complex than they seem, as we discover at the Panerai manufacture.

Stepping into the foyer, we were greeted by an oversized Luminor Marina and were reminded of its importance to the watchmaker. Miniature aquariums line the corridor as vitrines housing watches instead of fishes — a tribute to Panerai’s seafaring and naval involvement. Considering that much of Panerai’s past has been shrouded under the Military Secrets Act and withheld from public record, it is a clever and playful gesture as the mystique takes on a new form.

We begin our excursion at Laboratorio di Idee, the soul of Panerai’s forward motion. Despite the name, it is no romantic atelier of dreams; it is Panerai’s specialised think tank comprising up to 50 highly specialised workers. Futuristic ideas are conceived, prototyped and tested before being realised as real-world innovations or solutions.

Apart from core novelties, Laboratorio di Idee is responsible for the “Lab-Id” concept watches. The recent Submersible Elux Lab-ID PAM01800 and Submersible eLAB-ID PAM01225 still burns fresh in our minds, and it feels surreal to see the department responsible for those forwardthinking creations come to life.

Perhaps most emblematic of Panerai’s openness is the Submersible eLAB-ID PAM01225 Recycled Titanium project. Panerai publicised its complete list of contractors and collaborators involved in the project as a stark contrast to its days of military silence and even today’s industrywide discretion and veiled supply chains.

While the deliberate reversal is powerful in its own right, it signals a brand willing to reinvent not only materials but mindsets and perspectives. An average of four patents is filed annually as the department pushes the boundaries of what is achievable while maintaining the brand’s DNA and its unmistakable character.

Material innovations, a significant proponent of the present-day watchmaking industry, also come to life here. While some brands occasionally experiment with new materials, Panerai introduces a new material roughly every two years and is credited with innovative high-tech materials, such as the most recent Ti-Ceramitech™, DMLS (Direct Metal Laser Sintering) Titanium, Carbotech™, and recycled eSteel.

As part of Panerai’s commitment to reliability and robustness, a dedicated suite of tests happens behind the scenes to ensure the desired outcomes surpass international and internal standards. Given the brand’s naval past, water resistance remains one of the brand’s hallmarks. Watches undergo multiple rounds of waterproofness trials, one right at the very end just before delivery.

Apart from these, Panerai pushes the tests to simulate real world conditions through various testing protocols and ageing tests to ensure nothing is theoretical but baked into the watches. Once a watch design is prototyped and approved for production, it takes physical form in the machining department.

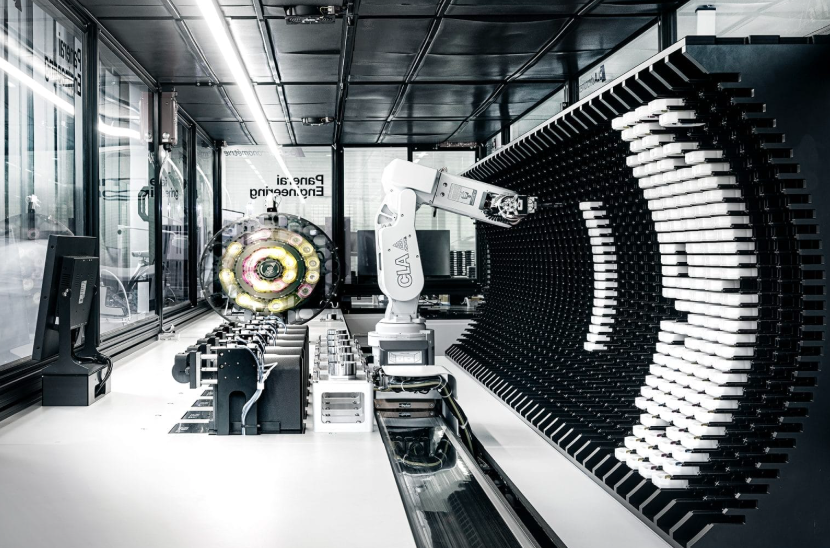

With over 20 modern CNC machines housed within Panerai’s fleet, the division is tasked with operating six days a week to produce up to 12,000 cases per year. Depending on the case’s complexity, it takes anywhere from 90 to 240 minutes to mill a case. Even though automation rules with clinical precision, every step is monitored under the watchful human eyes.

Eyes and now hands too take centre stage in the assembly department, away from the industrial precision of the rest of the manufacture. Watchmaker benches are lined with tiny vices, loupe stations, and time-graduated trays — each holding movements in various stages of becoming.

Where the bustle of science and innovation reigned supreme in the previous departments, this almost silent department echoes with heritage and tradition. Apart from dextrous hands, intuition and sensitivity are a watchmaker’s best friends as each gear, pinion and screw is layered atop one another until arriving at a finished calibre.

Cloistered away in a quieter section of the level is the Haute Horlogerie department. Everything seems to slow down here as Panerai’s stable of 10 master watchmakers apply skill and knowhow to assemble some of Panerai’s most complex references. These include the minute repeaters, perpetual calendars, tourbillons, and equation of time complications that are stretched beyond traditional configurations to fit Panerai’s philosophy. We got to witness a watchmaker working painstakingly on the Submersible Elux Lab-ID PAM01800 and this year’s pièce de résistance, the Jupiterium planetary.

Panerai’s manufacture is not flashy or performative, nor does it try to be. Its strength lies in contrast, with a symbolic transition reflecting a deep recalibration of what it means to build a watch in the modern age. Despite its commercial shift, the brand has retained its aura through ideas, innovations and storytelling. The difference between then and now is that you get to see how things are done today.

Once you are done with this story, click here to catch up with our latest issue.