Tudor was born of a bold premise in 1926: to offer watches with the quality and dependability of its elder sibling, but at a more accessible price point. Long before the term “tool watch” came into watchmaking lexicon, Tudor founder Hans Wilsdorf believed in building watches that could withstand the rigours of real-world conditions — watches designed to meet the needs of divers, militaries and explorers.

In the decades to come, Tudor quietly amassed a legacy of robustness and reliability through its relationship with naval forces and adventurers by supplying timekeeping equipment they could trust. A renaissance in its storied history beckoned: Tudor launched its Manufacture Calibres in 2015 and sharpened its modern identity with a renewed global presence with the Black Bay collection.

That journey — nearly a century in the making—now finds physical expression in Le Locle, where its first-ever dedicated manufacture marks a new chapter: one of total integration, in-house mastery, and a daring spirit made tangible.

Set in the Jura Mountains, near Switzerland’s border with France, Le Locle contributes to horology in ways that far outweighs its inhabitants. Amid the serenity of Le Locle, where time seems to take measured steps, one building breaks the rhythm against the muted palettes of its surroundings.

Cloaked in a defiant red, Tudor’s Manufacture stands as a modern bastion of precision, its facade echoing the boldness of its shield emblem. Here, in the heart of Switzerland’s historic watchmaking avenues, Tudor signals progress instead of nostalgia.

My day began at 7.30am, no thanks to the hour-and-a-half drive from Geneva. After linking up with Cole Pennington, formerly a voice at Hodinkee but now part of Tudor’s storytelling engine, and other media representatives, we were on our way towards the Tudor Manufacture. This was the visit I was looking forward to most, and as a Tudor owner, this trip felt more like a quiet pilgrimage for the Tudor Black Bay 58 Bronze strapped to my wrist.

Leading the tour was Régis Gaudimier, head of the Tudor Manufacture, and possibly the best person to do so. Gaudimier oversaw the Tudor manufacture project, which took three years to complete. Together with his knowledge of the processes and infectious enthusiasm, the walkthrough was all the more enjoyable. Since time was of the essence, we were whisked away by Gaudimier shortly after donning our protective workshop coats and shoe covers.

We began beneath the building itself, with a foundation that was measured, engineered, and built to last, ensuring the longevity of the structure. The project turned out to be more complicated than expected after discovering that the subterranean terrain was soft and wet, making it unsuitable for building construction.

The entire facility spans 5,500m² across five levels and is supported by 330 deep-set concrete pillars anchored into bedrock, further reinforced with 8,050m³ of concrete and 960 tons of metal framing. An extra waterproof membrane lines the foundation to fully shield the underground sections from water.

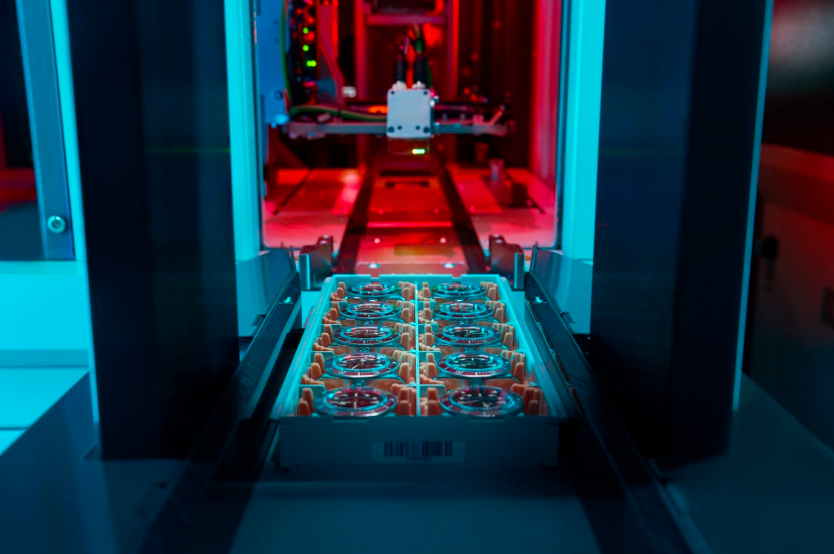

After the initial oohs and aahs, we discovered the tour involved a great deal of walking and stair climbing. We wound our way through several flights of stairs and corridors and arrived at the Automated Stock system. Tucked away behind concrete walls, the critical organ in Tudor’s logistical body orchestrates Tudor’s storage and dispatch system.

Whether it involves delivering unassembled components or fully assembled calibres, this interconnected network allows for optimised productivity, efficiency and delivery. Despite being a high-tech automated system, a coordinator oversees the entire operation during their shift to ensure everything, from the tiniest screw to a completed calibre, arrives exactly where and when it needs to. No clutter. No waiting. Just seamless, silent efficieny.

The Assembly Floor is where hands take over. Since dust is the sworn enemy of watch movements, a continuous airflow pushes micro-particles to the floor to prevent them from lingering in the air. Here, the air is fully renewed 3.5 times per hour or every 17 minutes.

Without exaggeration, my nasal passage cleared immediately upon entering the room, even though I had been battling sinusitis throughout my time in Geneva. Gaudimier was proud to inform us that the optimised environment was one level higher than NASA’s. Given the manufacture’s “no stock” policy, Tudor watches are built to order. This allows the brand to be agile in responding to market needs.

The fluid production nature means the watchmaking team has to be well-versed in every assembly operation through vigorous cross-training. Assembly is done in autonomous, compact four-person cells, regardless of the model they’re assigned to. Team members within a cell train together until they are fully operational, thereby strengthening team spirit, chemistry, and efficiency.

Each member is trained to assemble any reference spanning all of Tudor’s collections. All benches are arranged in the same manner, from their machinery to the contents and organisation of their drawers. As a result, this flat, cross-trained structure allows for flexibility and consistency, with each bench identically equipped for seamless transitions. Watching the process is like watching choreography: human hands guided by muscle memory, backed by real-time market demands.

We arrived at the Performance Control Floor soon after — the high-tech foil to the assembly floor’s humanised processes. Roughly 46 metric tons of super high-tech testing machinery operate 24/7 here in a fully automated, autonomous system. Every Tudor watch is tested here — every single one — according to two testing benchmarks: TPC (Tudor Performance Control), the brand’s internal standards, and METAS (Federal Institute of Metrology in Switzerland) Master Chronometer.

The former ensures every watch meets the accuracy criteria of -2/+4 (Manufacture Calibre) or -4/+6 (other calibres) seconds per day when fully assembled and meets waterproofness requirements in hyperbaric water tanks.

The latter subjects watches to more stringent checks across the functions of precision, resistance to magnetic fields, waterproofness and power reserve. It guarantees an accuracy of a five-second range of variation each day (0/+5) even when subjected to magnetic fields of 15,000 gauss. Waterproofness also has to meet ISO Standard 22810:2010 and certain power reserve levels.

The level of scrutiny is astonishing. Each test phase lasts either seven or 21 days. If a watch fails a specific test at any point, it must be reassembled before undergoing the entire testing process again. If the watches we admire on wrists are effortless, this is where the effort is distilled.

We finally arrive at the department that manually checks components, fits bracelets and engraves. Though less fancy than what we’d seen thus far, it is no less precise. The engravers also handle bespoke or limited series engravings. The watches undergo a final round of checks before leaving the building — mirror-polished surfaces are free of the slightest of scratches, and dials of dust specks — the last moment of contact before it reaches the outside world.

Three hours went by in what felt like half the time. We changed out of our lab coats and stepped back into the spring light of Le Locle. After one final wrist shot of my watch against the manufacture’s facade, it was time to bid goodbye to our hosts, to the manufacture, and its quiet intensity that pulsed within those red walls.

We hit the road once again, back to Geneva, with a full day of Watches & Wonders appointments awaiting us. Even though my legs felt tired, I left enriched knowing that my watch, just like every other before and after, is built on innovation but brought to life by a human hand. That is the daring spirit and paradox of Tudor.

Once you are done with this story, click here to catch up with our latest issue.